TOPSORT Colour Sorter Machine For Rice 8 core technologies are blessed,stronger applicability,and more durable. One machine has multiple sorting models,which can easily control the sorting needs of different colors,yellow,whites and other process points,and perfectly creat cost-effective sorting of popular items. It's your quality choice!

Order(MOQ) :

1Payment :

TT/LCProduct Origin :

Hefei,ChinaColor :

White,can customizeShipping Port :

Shanghai/NingboLead Time :

Within 10 working daysCertificate :

CEProduct Name :

Rice colour sorter machineWarranty :

2 yearsMachine Function :

Color/size/material sorting

TOPSORT Quality Rice Colour Sorter Latest Technology

1.30000+ RICE AND GRANULES DETECTING EVERY SECOND

Computing updating, new generation FPGA processing technology with ALTERA, TI high proformance chips, accurately discover the quality of the sorting products.Take rice for example, every second 30000+ rice granules detecting,accurately remove variety defects. The sorting accuracy are much higher, processing capability are much stronger. lt ensure the variety of defects, tiny spot, light trace are easily discovered.The wisdom helps us “what you see is what you get."

2. INTELLIGENT OPERATION SYSTEM

Overall Large Screen HD Operation control panel, 1080P S uper high resolution,Linux Operation system, system more stable, more friendly Human-Machine-Interface panel, which gives high sensitivity instant fast repones in the industrial environment.

3. NEWLY SPECIAL SUPER WIDTH CHUTE DESIGN

Special technology chutes, applicable for universal materials,make the transfer more steady, more capacity.

4. MECHNICAL RECONSTRUCTION

Reconstrution of the mechnical frame, the main part with special material,balancing whole frame bearing, ensure the machine integrity. Working with the updated mechanism, it strength the base of the ultra-sorting.

5. SELF-DEVELOPED SPRAY VALVE

Self-developed spray valve, Self-developed high-performance spray valve, super high rapid response to the Algorithm results. It can continuously working 12billion+ times, extremely long life, with low air consumption,master the core technology.

6. ILLIMITABLE SORTING POSSIBILITIES, START BY “ONE BUTTON” PRESSURING

Hundred of sorting profiles can be saved in machine machine, for the variety products for sorting, subdivide the quality of agric and si©deline products illimitable sorting possibilities,“one button”start, “one button”profiles exchange.

7. SHADOWLESS COLD LIGHT SOURCE,AUTOMATICA ADJUSTABLE

Extremely long life, low energy consumption intell ligent shadowless cold light source, orthogonal spectrum technology, make the image more visiable, more accuracy detection; the output luminance of light source are automatically adjustable, it make the lights more stable with high quality. It is fully appliable for the camera to see and detect.

8. WIRELESS REMOTE CONTROL FOR GLOBAL

Various terminals can be easily connected, remote control, instant response, and enjoy unattended operation.

Electronic Colour Sorter Property Followed

1.Equipped with high-definition 5400 pixels full-color sensor, high-definition capture functions, restore the true color of the material, photos can be 8 times enlarged to develop the image, high-speed linear scanning speed. Enhance the recognition of tiny defects and fresh water yellow.

2.Intelligent retesting easy selection algorithm system to enhance the parallel analysis and processing capabilities, easy to create a robust selection mode, and can achieve a variety of independent color sorting, positive selection, anti-selection, re-selection, etc., durable and stable. More outstanding sorting effect.

3.High brightness LED cold light source,shadowless illumination,stable and durable lighting environment.

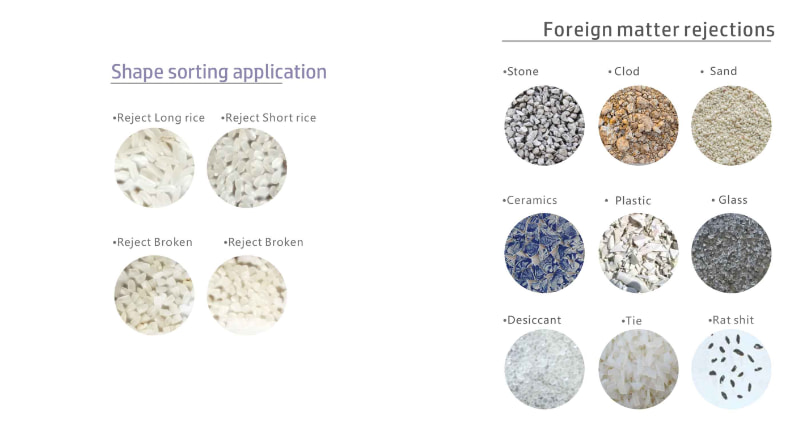

4.Transparent, plastic and non-metallic particles and different colors can be sorted. particles of different sizes, shapes and even physical properties. Infrared see-through technology can effectively solve the problem of sorting materials when they overlap

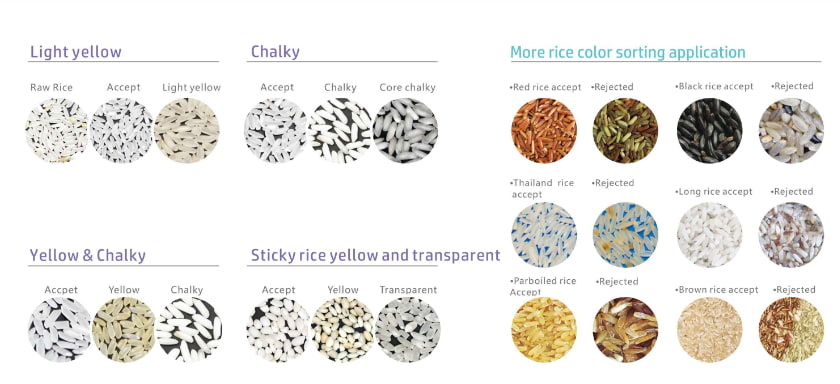

TOPSORT Rice Sorting Sulotions

Sucessful Cases

24 Managed Care Services

|

1. Core Component Inspection 2. Air Filter Inspection 3. Dust Cleaning Effect Inspection 4.Environmental Temperature Monitoring 5. Ash Cleaning Unit Monitoring 6.Camera Color Drift Monitoring 7.Optical Path Pollution Monitoring 8. Feeding System Monitoring |

9.AI Intelligent Sorting 10.Carryover Ratio Monitoring 11. Background Color Monitoring 12.Identification Parameter Monitoring 13.Precise adjustment of Cleaning Cycle 14.Precise adjustment of Unit Division 15.Optical Aberration Monitoring 16. Remote Information Management System |

17. Operation Tracking 18.Aberration Correction 19.Software Upgrade 20.Background Monitoring 21.Spray Valve Monitoring 22. Air Pressure Monitoring 23.Remote Commissioning 24.SMS Notifications |

Welcome your inquiry~